Envelope Construction

Discover the advanced construction of Kubíček hot air balloon envelopes. Designed for durability, performance, and safety, our envelopes set industry standards in quality.

Discover the advanced construction of Kubíček hot air balloon envelopes. Designed for durability, performance, and safety, our envelopes set industry standards in quality.

The envelope is the most visible component of the balloon. From the legal point of view the envelope is considered as the aircraft (while basket, burner and fuel tanks are considered as aircraft parts). As such the envelope holds the serial number and national registration marks.

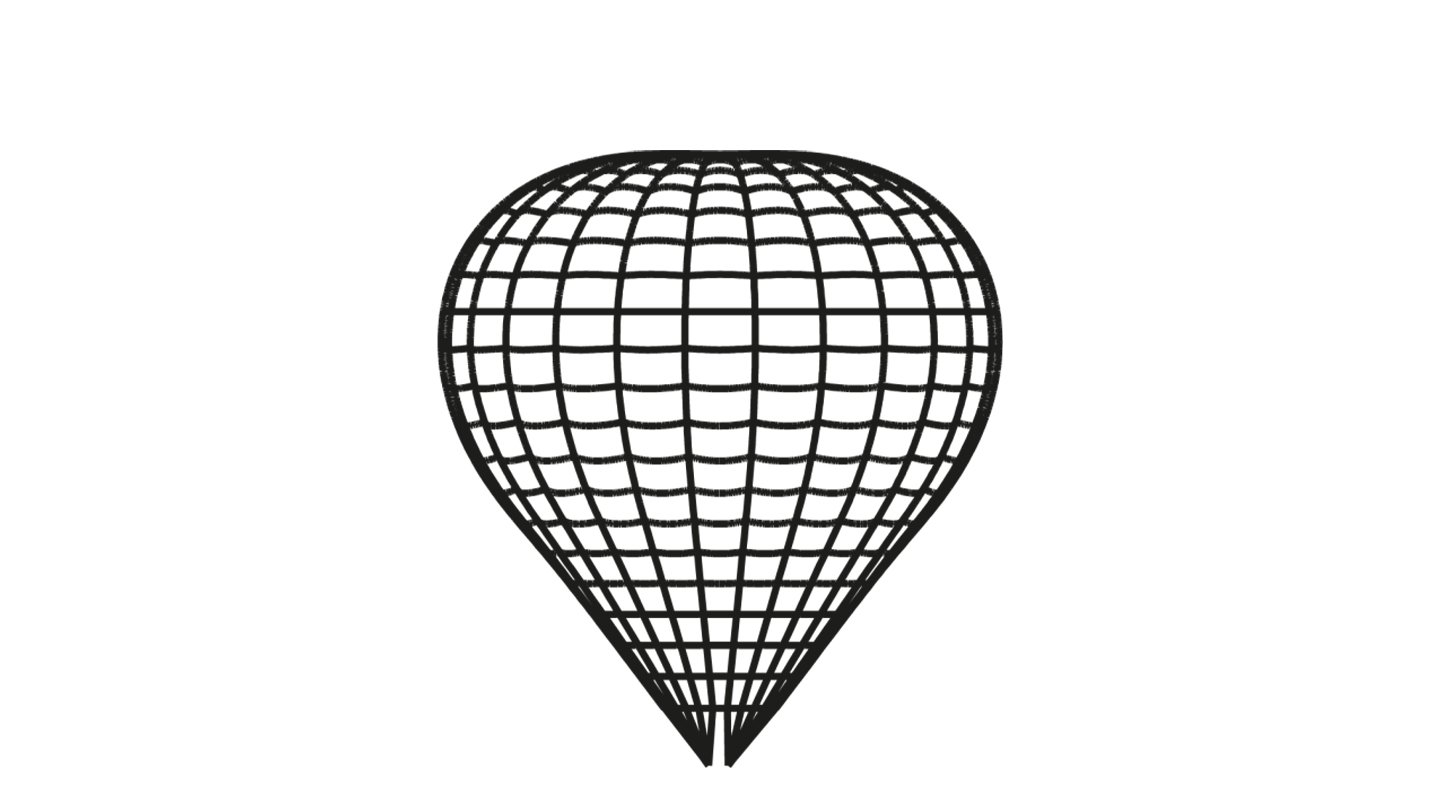

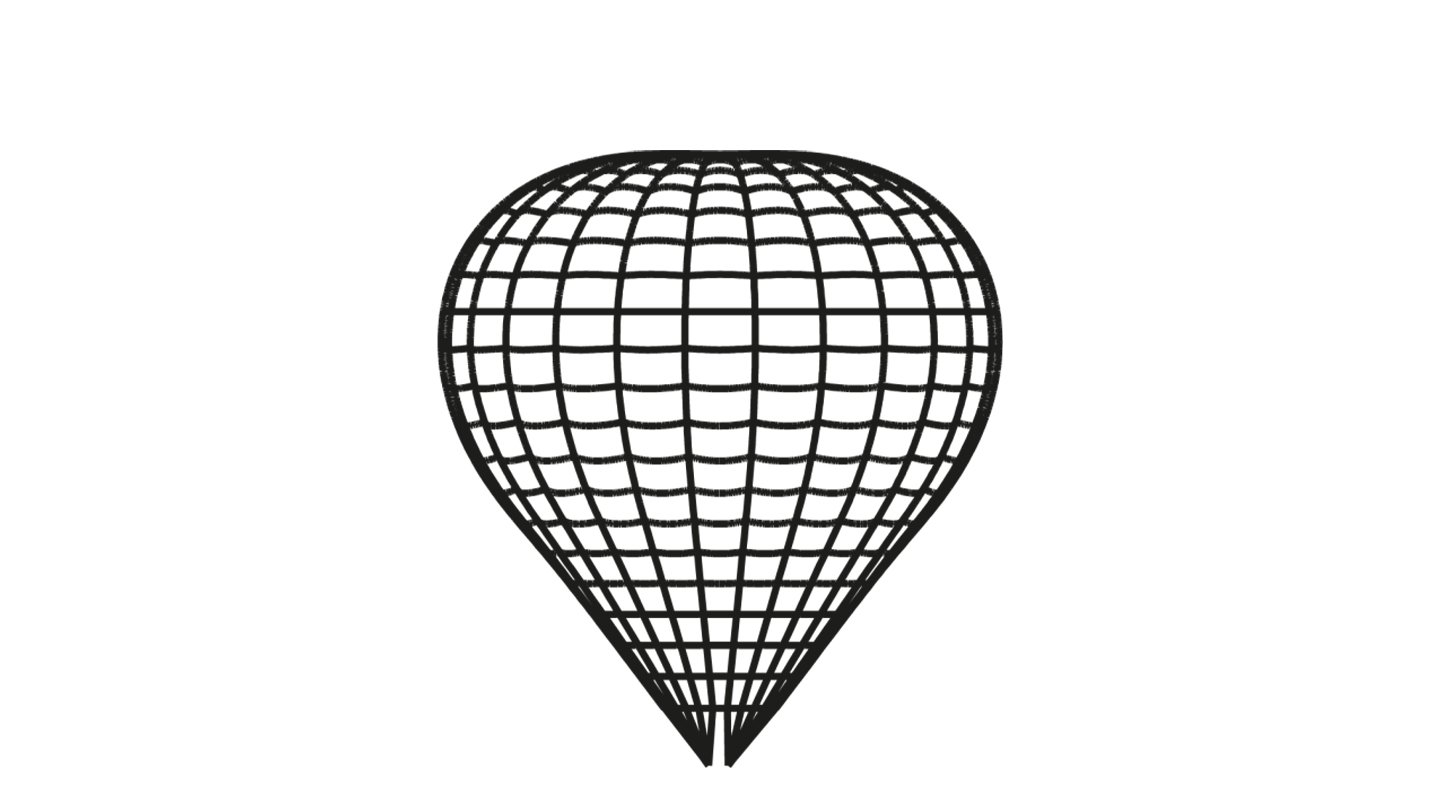

Each envelope series has its own characteristic shape designed for a specific purpose. However, they all come from one basic shape - the Natural Shape. In simple terms the Natural Shape is one in which the fabric only stretches by the internal pressure while the entire basket load is carried by the vertical load tapes.

There are a number of variables within the equations that the design engineer’s use and these result in the different balloon manufacturers developing envelopes that, although similar, are not identical.

As we have mentioned before, the weight of the basket is carried by the envelope’s vertical load tapes. The load tapes form the major part of the “primary load path” which runs all the way down from the crown ring, through the vertical load tapes and then through the attachment points to the flying cables and karabiners to the balloon’s burner frame and basket wires. All these components are critical to the safety of the balloon. When the balloon is being used or inspected it is very important to pay close attention to these parts. If damage, beyond the limits stated in the Maintenance Manual, is found then the balloon is unairworthy until the damage has been repaired by an authorised repair station.

Load tapes are made from Polyester because it degrades slowly and has a high UV endurance. Because the load tapes are thick they degrade more slowly than the envelope fabric so there is no need to measure their strength during the balloon‘s operational life. The attachment points at either end of the load tapes are sewn with a special double stitching that ensures that they will not fail.

The horizontal load tapes prevent the propagation of potential rips in the envelope fabric. They are not part of the primary load path

Horizontal load tapes are not used in diagonally cut envelopes as any damage to the fabric of the envelope would be stopped as soon as it reached a vertical load tape.

The fabric is the most discussed part of a hot air balloon. Its quality determines the balloon’s overall quality. That’s why Kubicek develops and produces its own polyester balloon fabric

For flight safety, all envelopes have an indicator for the maximum operating temperature. Each envelope is equipped with either a simple Melting Link or an electronic temperature sender (e.g., Flytec 3040). Only one measurement method is needed, so a balloon with electronic temperature measurement does not require a Melting Link.fd