Keeping Burner Hoses on the safe side

Proper use and maintenance of burner hoses are crucial for the safety of your hot air balloon, as well as for ensuring the longest possible lifetime of the fuel hose.

Proper use and maintenance of burner hoses are crucial for the safety of your hot air balloon, as well as for ensuring the longest possible lifetime of the fuel hose.

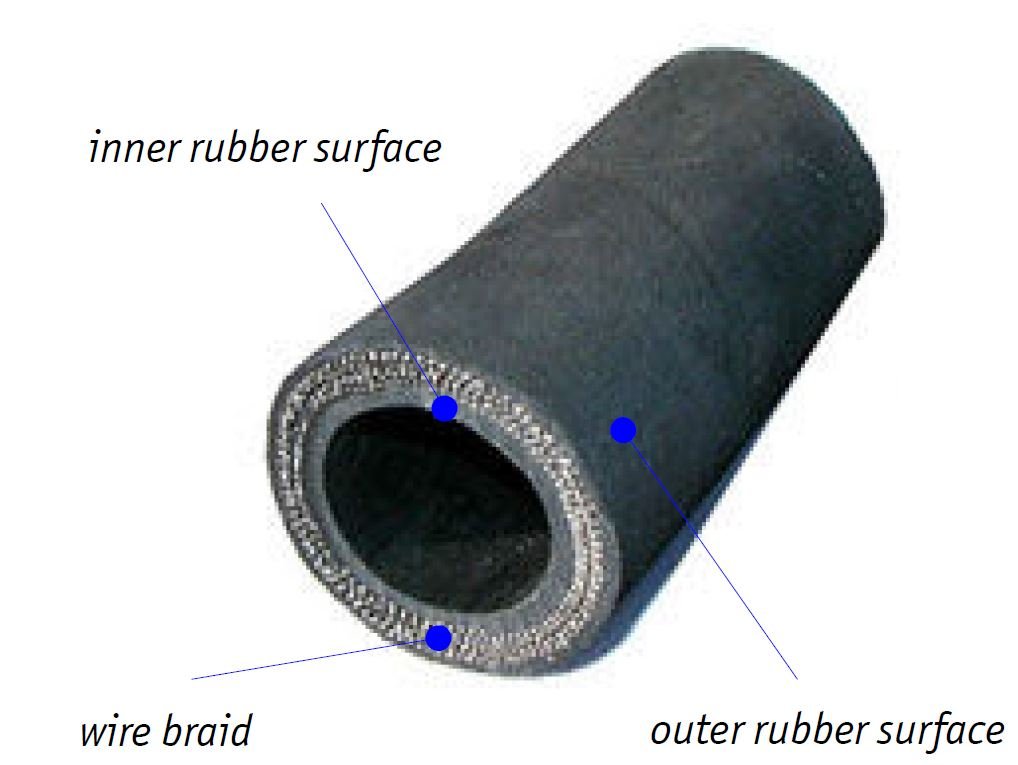

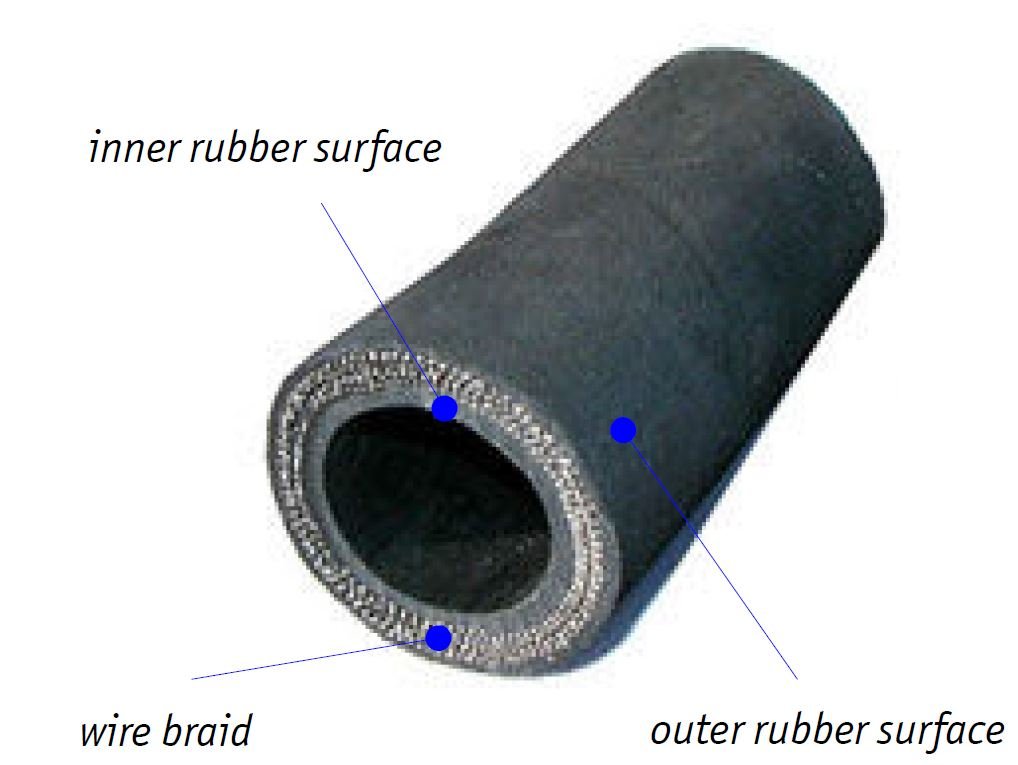

The hose is designed to withstand high pressure, mechanical damage, transportation effects, and external impacts. The fuel hose consists of three basic layers:

What most affects the hoses is sunlight and UV light, high temperatures, ozone, and organic resolvent. This is even worsen when the hose is in any kind of pinched position, e.g. bent at a sharp angle. For Kubicek hoses, the tightest bend allowed is with a diameter of 90 mm.

Over time, the hose dries out and its outer layer stiffens, resulting in cracks and tears in the hose. When the damaged hose is bent, dirt can get into the hose and affect it from the inside. And the whole process accelerates…

When a tear is so deep that sunlight and other harmful effects can reach the inner layer, the situation worsens quickly. The inner layer is not designed to resist outer effects. In extreme cases, the inner layer can crack and fuel may leak.

When propane is in contact with the inner layer of the hose over a longer term, it can damage the gas-proof aspect of it. This damage is impossible to see while examining the system and may result in gas leaks.

There are two basic rules for using fuel hoses:

Other very important aspects of usage of the fuel hose

The 10-year lifetime of balloon hoses is possible only when great care is taken while using them. Even then, there are many cases when the hoses have to be replaced earlier. We recommend observing as many of the above points as possible. This is how to ensure that the hoses will serve you for the longest time.